1: How to determine the quantity and spacing of your cantilever arms.

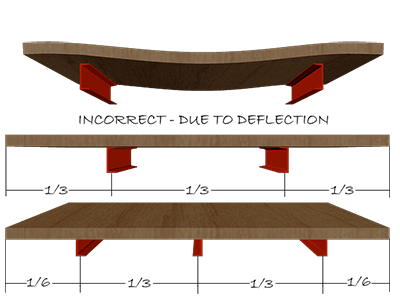

1. You Should always use enough cantilever arms under the product to prevent any deflection. Deflection of the product can cause damage to the product itself in some cases and will cause undesirable side pressure on the cantilever arms. Determining the right amount of cantilever arms needed to support your products without any deflection is easy. Simply take two wooden blocks or maybe 2 x 4’s and place them on your floor. Then you place your product on the blocks to test the load for deflection. With this test your are determining if your load can be supported by only Two (2) cantilever arms. You can adjust the width between the blocks until you start to see any deflection. It is a very good idea to never have the cantilever arms spaced apart more than 1/2 the length of the product you are storing.

2. If you detect any deflection then you have reached the maximum distance the cantilever arms can be apart in your cantilever rack system. Choose a distance that is in even numbers because cantilever braces come in 2′ wide to 8′ generally. Remember the rule of never having the cantilever arms spaced apart more than 1/2 the length of your product.

3. If there is any deflection when using two (2) cantilever arms then try Three (3) cantilever arms under your product. When correctly loading your Cantilever rack the product should only overhang the cantilever arms by 1/2 of the cantilever upright centerline distance. Loading the products without overhang is incorrect and dangerous.

2: How to determine the right Cantilever arm length.

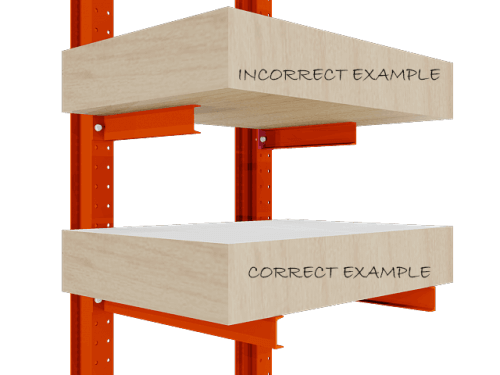

The Cantilever Arm Length should always equal the product load depth.

3. How to determine the correct cantilever upright height.

*Remember to consider the clear height in your building and the maximum height your forklift will lift minus about 4″ so that you can actually lift the product on and off the cantilever arms. Now you’re ready!

*Remember to consider the clear height in your building and the maximum height your forklift will lift minus about 4″ so that you can actually lift the product on and off the cantilever arms. Now you’re ready!

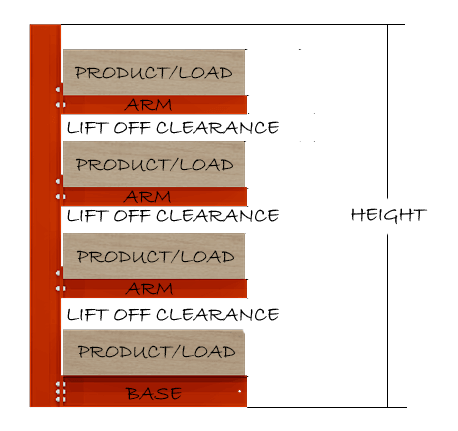

You will first start by giving consideration to the cantilever base height. Next you will look at the number of storage levels you can achieve by reviewing the following: Load Height: This is the total distance from where the product/load will sit on the Cantilever Arms to the top of the product/load. Don’t forget the 4″ inches of “Lift off” distance that you will need to place the product on and off the cantilever arms with your forklift. 6″ is even better. Cantilever Arm Levels: Each arm level will take up a certain amount of space. Cantilever Arms come in different heights due to different capacity requirements. Generally they are 3-4 inches tall. You simply give consideration to the specific height of the cantilever arms you are using in your cantilever rack system. Cantilever Upright Height: The Cantilever Upright should generally be 4″-6″ taller than the top of your highest load that you will be storing. The top cantilever arm level should always be below the top of the Cantilever upright column.

4: How to determine the required cantilever arm capacities.

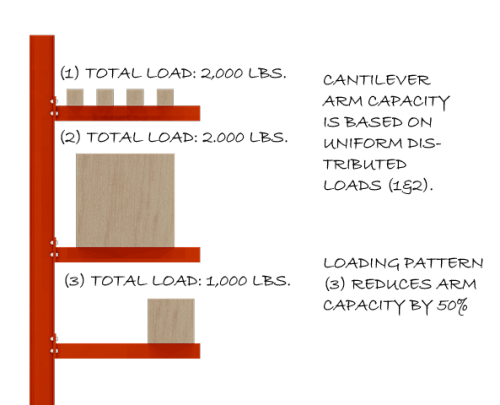

You simply take the “Load” weight and divide that by the number of arms it takes to support the load without any deflection. This is based on an uniformly distributed load on the Cantilever arms. Uneven loading will reduce the Cantilever arm capacities by 1/2!

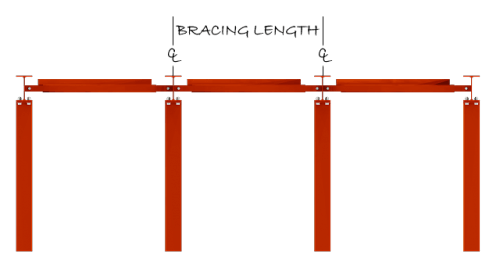

5. How to determine the Cantilever Bracing Lengths

Cantilever Bracing length refers to the distance between the Center line of the Cantilever Uprights shown in the diagram above. To determine the size you need you will refer back to step 1 above.Cantilever bracing generally comes in single horizontal braces and one piece brace panels or kits. Feel free to call us with any questions you may have when configuring your cantilever rack system. Our trained professionals can help you determine just what you need so that you can efficiently store your products in your warehouse.